ROCK REINFORCEMENT

– Patented methods for monitoring and surveillance of rock bolts

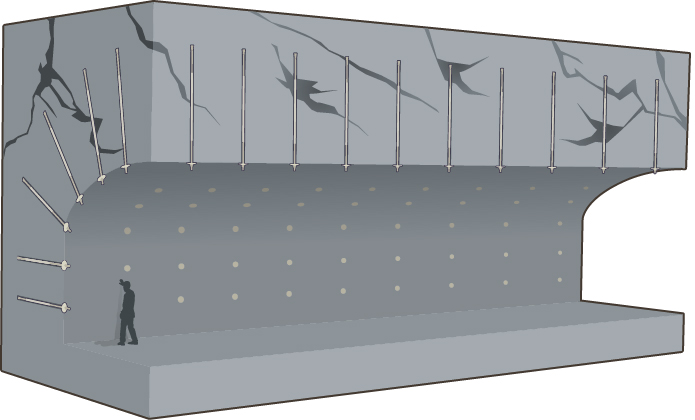

World-wide, about 100 million grouted rock bolts are installed annually, most of them underground, some to reinforce rock slopes. Water in cracks and insufficient grouting are problems that can result in corrosion and later on to bolts breaking.

These are old-fashioned and unnecessary risks in an already risk-filled environment.

Now there is a technique that makes it possible to expose problems before they lead to negative consequences.

Optimal safety requires completely grouted rock bolts. With Rock Safety System’s patented products you can “see below the surface”. With CaviTube mounted on the rock bolt you can monitor and document the installation. If you also choose Bolt Status Wire, and combine it with your choice of sensor technology, you can also continuously monitor how the bolt stretches under many years to come. This saves time and money as well as increasing accessibility and safety. Link to our leaflet (PDF)

This method fits almost

all rock bolts

Mines, road and train tunnels, rock cavities or rock slopes. Longevity, safety demands and accessibility varies – this is why we offer custom tailored solutions!

The Cavi method saves time and money

How do you know that the rock bolt is correctly grouted and how do you know the status a few years later? It is hard to know if the bolt is fully injected, if a bolt has broken off inside the rock mass or how much elongation has occurred along a dynamic bolt inside the rock. Installation monitoring and status surveillance of grouted rock bolts have been problems for a long time. CaviMeter and our sensor program solve these problems and fit all types of cement-grouted rock bolts.

Rock Safety System’s Cavi products for grouted bolts are unbeatable for monitoring and documentation of installation as well as the surveillance/analysis of rock bolt status over time. No other system provides information with such precision and in a so accessible manner. It is a direct-measuring method, in contrast to other alternatives. You get the results of the measurements immediately, without detours, via analyses and assumptions. Right away you can see whether the rock bolt is fully grouted or not.

There is a significant savings potential in ensuring correct installation. The reduction in manpower hours and avoiding drift stops is the result of choosing the detection method for status monitoring that fits your needs. But most important is the increased safety in a risk-filled environment that all work underground entails.

This is how it works

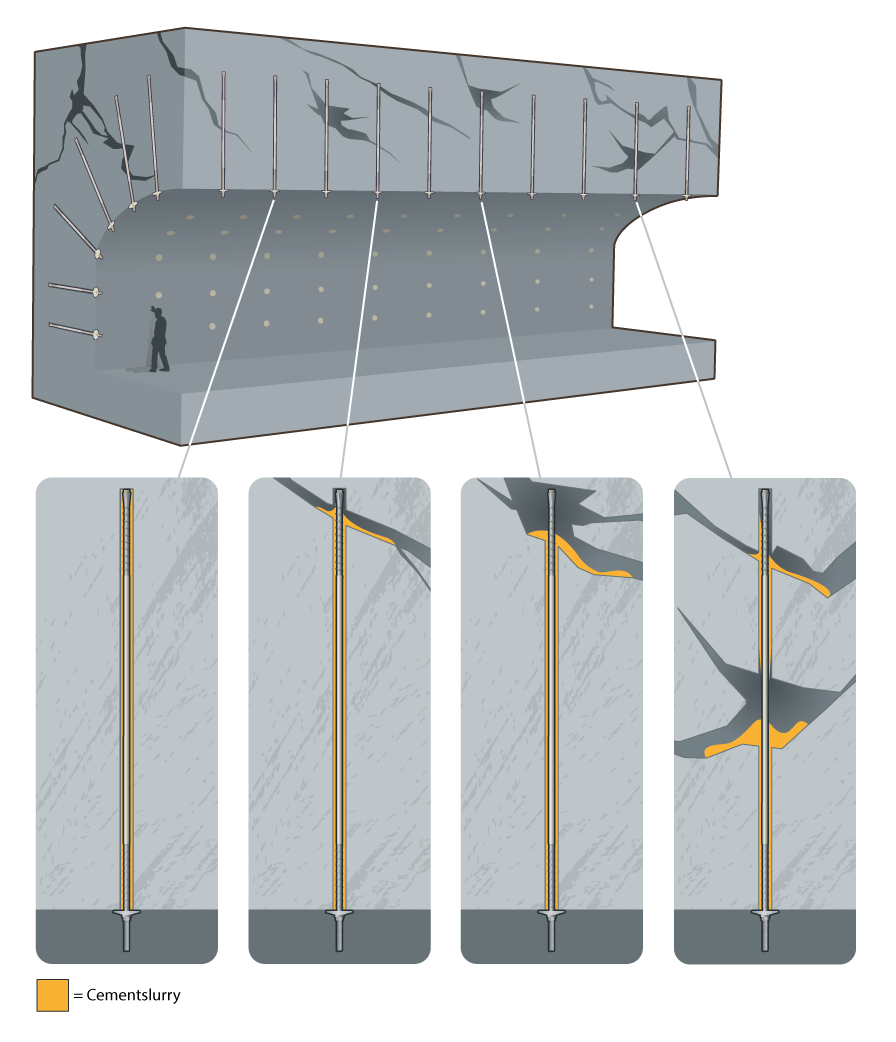

CaviMeter works by fitting the rock bolt with a thin plastic tube with two small slits. When the bolt has been installed the tube is pressurized with gas to detect any cavities or cracks. If there are any cavities in the injection grout, the gas will fill the cavities and the measuring equipment calculates their size.

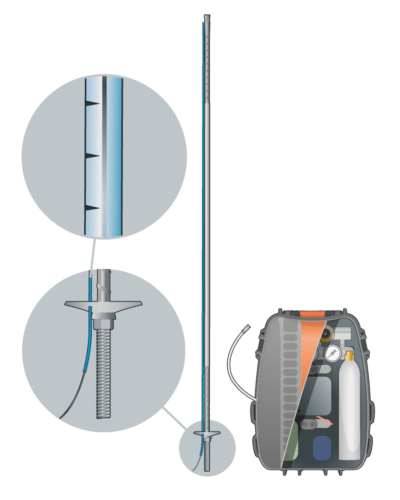

Those who choose the simplest sensor, CaviBasic, have a wider range of possibilities. A metal wire is then fitted inside the plastic tube to also allow for status surveillance over time and with your choice of detection method. In this case, we offer CaviLight, CaviSense and CaviCom that show the status of the rock bolt in different ways.

Installation monitoring of grouted rock bolts

With CaviMeter, the installation of grouted rock bolts can be securely monitored and documented. A plastic tube is fitted along the bolt and the installation is pressurized with gas to discover and measure any crevices.

CaviBasic is a further-developed version of CaviMeter that enables the user to monitor the status of the rock bolt over time. CaviBasic must be chosen at the start of installation.

Prevent

costly

re-grouting

Products for installation monitoring

Product description and technical specifications. Click on the name of the product.

Status surveillance of grouted rock bolts

A plastic tube with small cuts is fitted on the rock bolt to enable installation monitoring. Within the tube there is a thin metal wire that enables status surveillance. For rock bolts with CaviBasic, there are three alternatives for reading the information on bolt status. All three have sensors are completely sealed in plastic and can take tough underground environments.

Bolt Status Light is a sensor that is screwed on to the thread of a rock bolt. When the sensor comes in contact with the end of the bolt, the sensor’s electronic unit switches on. Bolt elongation and breakage is indicated by a red LED.

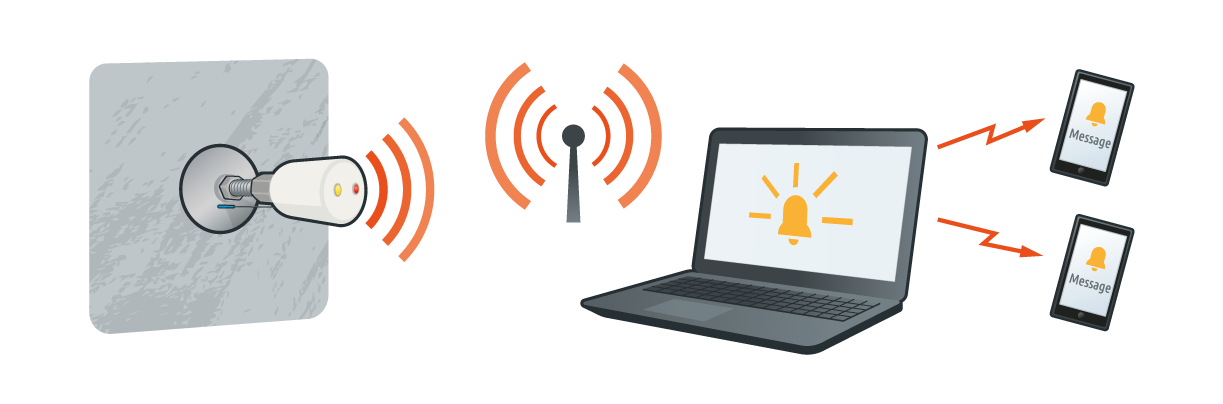

Bolt Status Online has an energy-efficient power unit that communicates with your internal network and enables presentation of rock bolt status on a central computer.

Bolt Status Online for continuous monitoring of rock bolts is a user friendly and robust system for increased safety. Bolt Status Online monitors rock bolt elongation and breakage with clear presentation of results online.

Unbeatable for monitoring

and documentation of

grouted rock bolts.

Products for status surveillance

Product descriptions and technical specifications. Click on the name of the product.

References

Product film from Rock Safety Sweden

Watch this film about the patented Cavi method. CaviMeter works by fitting the rock bolt with a thin plastic tube with two small slits. When the bolt has been installed the tube is pressurized with gas to detect any cavities or cracks. If there are any cavities in the injection grout, the gas will fill the cavities and the measuring equipment calculates their size.

The development project Mining for Generations

This film is about an ongoing development project in cooperation with Atlas Copco, LKAB, Rock Tech Centre, Luleå University of Technology and Rock Safety Sweden.

Research article at international conference

Luleå University of Technologyin Sweden is hosting Ground Support 2016. This is the 8th international conference about Ground Support in Mining and Underground Construction.

Experts from many different countries will meet on 12 – 14 September 2016 at Kulturens Hus in Luleå, Sweden.

Rock Safety Sweden will be presenting a research article: Sensor Techniques to monitor installation and status of rock bolts (Gustafsson, L.K.K.A.). Download the article here (PDF).

“It’ll be really exciting to see how well it can measure the load and deformation in the rock.”

– Lars Malmgren,

Section Manager R&D LKAB

Contact us today!

Rock Safety Systems with Installation and Bolt Status products are developed and owned by Rock Safety Sweden AB. We are leading systems-technology company within installation control and status monitoring of rock reinforcement in mining, in tunnel work for hydropower, road and railway tunnels, bore hold storage etc.

Please contact us to learn more.

Sales: Göran Remahl +46 70 555 59 10, goran.remahl@rocksafety.se

Technology: Leif Gustafsson +46 70 333 44 22, leif.gustafsson@rocksafety.se

Contact

Rock Safety Sweden AB

Nordkalottvägen 14

S-972 54 Luleå

info@rocksafety.se